| Sign In | Join Free | My wpc-board.com |

|

| Sign In | Join Free | My wpc-board.com |

|

| Categories | High Temperature Alloy |

|---|---|

| Brand Name: | KAIXIN |

| Model Number: | KX-Alloy HT4141 |

| Certification: | ISO9001:2015 |

| Place of Origin: | China |

| MOQ: | 200KG |

| Price: | To negotiate |

| Payment Terms: | T/T, L/C |

| Supply Ability: | 50~80TONS per MONTH |

| Delivery Time: | 45~60days |

| Packaging Details: | Wooden Box, size as per guests request |

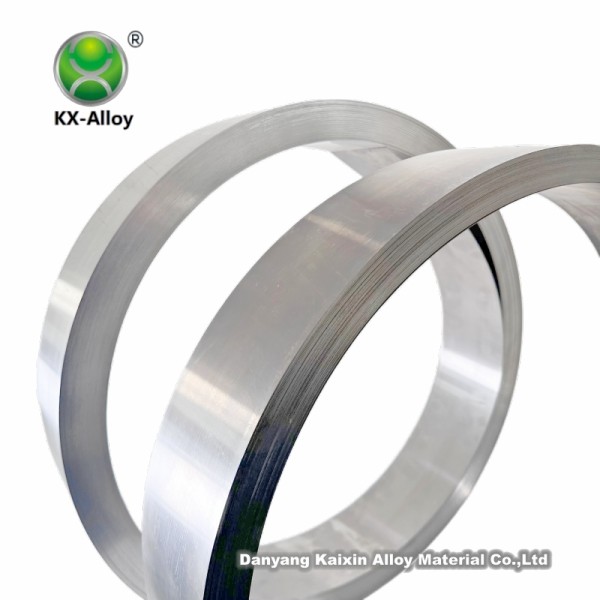

| Shape: | Wire, Strip, Rod, Tube, Plate |

| Alloy Type: | Precipitate-hardened nickel based Deformation Superalloy |

| Raw Materials: | NI Rem,CR18-20%,Mo9-10.5%,Co10-12% |

| Executive Standard: | ASTM,GB/T |

| Delivery State: | Sosoloid |

| Application: | High temperature parts for aerospace engines |

| Features: | Corrosion resistance, high tensile strength,persistent creep strength and good oxidation resistance. |

| Size: | Negotiable |

| Company Info. |

| Danyang Kaixin Alloy Material Co., Ltd. |

| Verified Supplier |

| View Contact Details |

| Product List |

Product Description and Application

UNS NO7041 is also known as GH4141,R41,Carpenter 41

UNS NO7041 is precipitate-hardened nickel based deformation superalloy with high tensile strength, permanent creep strength and good oxidation resistance in the range of 650 ~ 950℃. Due to the high content of aluminum, titanium and molybdenum in the alloy, it is difficult for ingot formation, but the deformed material has good plasticity. It can be cold formed or welded in the annealing state and the strain aging cracks are easy to occur during the welded parts heat treatment. It is mainly used in the manufacture on the heating surface components of various gas turbine, industrial furnace and etc equipment , such as burner tube plate and collecting box, hot gas duct and flue pipe.

Process Performance and Requirements

Vacuum Induction Furnace(VIM) and Electroslag Remelting Furnace(ESR)

| Alloy | % | C | Cr | Co | Mo | Al | Ti | Fe | B | Zr |

| GH4141 | Min | 0.06 | 18 | 10 | 9 | 1.4 | 3 | 0.003 | ||

| Max | 0.12 | 20 | 12 | 10.5 | 1.8 | 3.5 | 5 | 0.01 | 0.07 | |

| % | S | Mn | P | Cu | Pb① | Bi① | Sn① | As① | Sb① | |

| Min | ||||||||||

| Max | 0.015 | 0.5 | 0.015 | 0.5 | 0.001 | 0.0001 | 0.0012 | 0.0025 | 0.0025 |

| Density | ρ=8.27g/cm3 |

| Melting Point | 1316~1371℃ |

(1)When the parts are required to have high tensile strength and fatigue performance at low temperature,it is recommended to use 1080℃, air cooling +760℃, 16h, air cooling

(2)For working at high temperature and requiring material to have high thermal strength, the appropriate heat treatment specification is 1180℃, air cooling +900℃, 4h, air cooling.

(3)For ring parts and etc parts that require welding, it is recommended to use 1120℃, 30min, air cooling +900 ℃, 4h, air cooling.

Professional Customization

| Cold-drawn Wire | ¢0.3~¢18mm(Delivery in rolls or trays) |

| Hot-Rolling Wire | ¢5.5~¢20mm(Delivery in rolls) |

| Strip | thickness 0.1~4.5*width 6~350mm(Supply in rolls or straight strips) |

| Smooth Forged Rod on a Lathe | ¢60~350mm,L800-2500mm |

| Hot-rolled Burnishing | ¢20~80mm,L1000-5000mm |

| Cold Drawn and Burnishing | ¢2.5~18mm,L1000-8000mm |

| Seamless Tube | ¢1~275mm,wall thickness 0.2~30,L1000-8000mm |

|